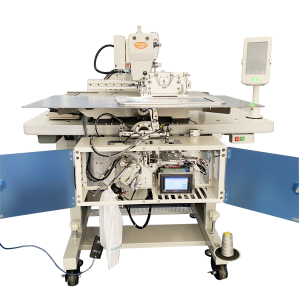

Computerized Pattern Sewing Machine CC-4530G-01A

Computerized Pattern Sewing Machine CC-4530G-01A

| Model | CC-4530G-01A |

| Sewing area | Max.45×30cm |

| Line | single needle sewing |

| Highest sewing speed | 2700rpm |

| Feeding device | Intermittent feeding (pulse motor driven mechanism) |

| Stitch length | 0.05-12.7mm |

| Max.stitches | 20,000 stitches/pattern |

| Work clamp lifter | pneumatic (height:max.30mm) |

| Clamp lifter | all in one |

| Clamp lifter ascension range | 22mm |

| Hook | double shuttle hook (Hirose Janpan) |

| Belt | Opti Germany |

| Sensor | Omron Japan |

| Valves | SMC Japan |

| Tension device | electric tension device optional |

| Data storage | USB or Memory card(CF card can save and edit any sewing patterns) |

| Motor | AC servo motor 750W |

| Air pressure | 0.5Mpa 1.8L/min |

| Net weight | 280kg |

| Gross weight | 350kg |

| Packing | 140*126*142cm |

| CBM | 2.5m³ |

Electric pattern sewing machine with servo motor drive

Large stitching area which can sew shoe upper, leather bag and other heavy fabrics.

LCD touch panel control system (optional)

adopted energy saving technology for low consumption and environmental protection.

Latest double action thread trimming device enhances the sewing quality, reduces the bird's nest.

Multi-use in shoe upper sewing, shoe-pad sewing,leather sewing, label sewing,velcro sewing,belt sewing, braid and webbing sewing,etc.

Improved traditional stepper motor feeding way, on the basis of the previous resolution of 0.05 mm increased five times, using the servo system control, the resolution reached the same industry and the high resolution effect, in the process of sewing a figure, resolution of 0.01 mm, and feed way faster, noise compared with the previous models, dropped by 10 db, More improvements have also been made.

High precision servo control cloth feeding mechanism, with positioning compensation software control system, can still achieve accurate and stable sewing stitches in high speed sewing/thick material sewing, effectively improve the traditional model will appear deviation, deviation phenomenon

The feeding method of the traditional stepping motor is improved, and the resolution is increased by 5 times on the basis of the previous resolution of 0.05mm.

Using the servo motor control, the resolution has reached the highest resolution effect in the same industry.

In the process of sewing a pattern, the resolution The rate reaches 0.01mm, and the feeding method is faster, the noise is reduced by 10db compared with the previous model, and the stitch has also been greatly improved for shoe sewing machine

this special industrial sewing machine using high-precision servo control cloth feeding mechanism, with positioning compensation software control system, it can still achieve accurate and stable sewing stitches during high-speed sewing/heavy material sewing, effectively improving the deviation and running position that traditional models will appear